PTP Sheets

"PTP Sheets" have excellent properties of high moisture permeability, transparency and formability.

Currently, PTP Sheets are used for packagings of tablets and capsules, and are widely known as a package configulation of having safety, stability and effectiveness and furthermore increasing the protection of the quality

PTP Sheets, which are manufactured by Taisei Kako, have advantages of formability and translucency while overcoming the difficulties in the packaging for pharmaceuticals.

Many kinds of our portfolios can be used for your wide range of your applications.

Grades and advantages of "Series"

| Series | Product | Total thickness (μm) |

Advantages | Material construction | |

|---|---|---|---|---|---|

| TAS-0000 | TAS-0125 | 250 | ・Impact resistant grade |  |

|

| TAS-0130 | 300 | ||||

| TAS-2000 | TAS-2225V | 250 |

|

|

|

| TAS-2230V | 300 | ||||

| TAS-2230VSD | |||||

| TAS-2230VSD Orange |

300 |

|

|||

| TAS-2230VHSD | 300 |

|

|||

| TAS-3000 | TAS-3230V | 300 |

|

|

|

| TAS-200 | TAS-225 | 250 |

|

|

|

| TAS-225SD Orange |

|||||

| TAS-230 | 300 | ||||

| TAS-235 | 350 |

|

|||

| TAS-240 | 400 | ||||

| TAS-300 | TAS-330 | 300 |

|

|

|

| TAS-C | TAS-C220 | 200 |

|

|

|

| TAS-C225 | 250 | ||||

| TAS-C230 | 300 | ||||

| TAS-C235 | 350 | ||||

| TAS-C240 | 400 | ||||

| TAS A2 | TAS A2-R227 | Rx 20e |

270 |

|

|

| TAS A2-U230 | UltRx 2000 |

300 | |||

| TAS A2-U333 | UltRx 3000 |

330 | |||

| TVS | TVS-115 | 150 |

|

|

|

| TVS-120 | 200 | ||||

| TVS-125 | 250 | ||||

| TVS-120ip | 200 |

|

|||

| TVS A | TVS A-R220 | Rx 20e |

200 |

|

|

| TVS A-R222 | 220 | ||||

| TVS A-R227 | 270 | ||||

| TVS A-U220 | UltRx 2000 |

201 | |||

| TVS A-U223 | 231 | ||||

| TVS A-U225 | 251 | ||||

| TVS A-U230 | 301 | ||||

| TVS A-U320 | UltRx 3000 |

206 | |||

| TVS A-U325 | 256 | ||||

| TVS A-U328 | 276 | ||||

| TVS A-U333 | 326 | ||||

| TVS A-U420 | UltRx 4000 |

202 | |||

| TVS A-U428 | 282 | ||||

| TVS AA | TVS AA-1722 | Accel 1700 |

223 |

|

|

| TAS-BPC | TAS-BPC2525 | 250 |

|

|

|

| TAS-BPC2530 | 300 | ||||

| TAS-BPC5025 | 250 | ||||

| TAS-BPC5030 | 300 | ||||

Advantages of CPP Sheets (TAS-0000・2000・3000)

【Advantages】

- TAS-0000 Series: Properties of having high impact resistance and superior transparency.

- TAS-2000 Series: Modified PP is used for the core layer of TAS-2000 Series. Due to this, both properties of moisture permeability and extensibility are souped up.

- TAS-3000 Series: Higher grade of TAS-2000 Series. Due to the coating of PVDC latex to TAS-2000 Series, both properties of moisture permeability and gas barrier property are souped up.

Advantages of COC (Cyclic Olefin Copolymer) Sheets (TAS-200 and 300)

【Advantages】

- In comparison with conventional CPP sheets, COC Sheets have higher moisture-proof property.

- In comparison with CPP sheets, COC Sheets have higher transparency.

- Blister machine for PVC sheets is possible to use for the COC Sheets, and after the forming, of them, the curling occurs almost none.

- Due to olefin resin, no hazardous gases / substances will be generated in the incineration (Except TAS-300)

Advantages of COC Sheets (TAS-C)

【Advantages】

- Thickness of 200μm that was realized for the first time in polyolefin resins and will surely contribute to the reduction of the waste.

- Water Vapour Permeability of the COC Sheets is on the same level as current COC Sheets. Excellent in moisture permeability.

- Due to the co-extrusion molding without adhesive agent, this will make it possible to conform to the VOC (Volatile Organic Compounds) Regulation.

- Low temperature forming is possible, and the range of the temperature is about 2 times of the PP.

- Due to the low curling property and the amorphous material, they will make it easy to half-cutting.

Advantages of CPP Sheets laminated with PCTFE (TAS-A2)

【Advantages】

- CPP Sheet laminated with PCTFE (Aclar®) high barrier property film.

- In comparison with conventional PTP sheets, PCTFE sheets have extremely high barrier properties of moisture and gases.

- Since the base material is made of CPP Sheets, your current-use machine is usable.

- Our current-use material named Aclar® is registered in DMF of US FDA.

※PCTFE: Polychlorotrifluoroethylene

※Aclar®: Registered by Honeywell

Advantages of PVC (TVS) Sheets

【Advantages】

- Taisei's PVC sheet has a light shielding property even in the ordinary grade and due to no additive of UV organic absorberbent agent that makes free from concern about its influence on the drug.

- No peculiar odor is smelled during the blister forming.

- Wide range of molding temperature with proper formability.

CPP Sheets Laminated with PCTFE (TVS A)

【Advantages】

- PVC Sheets laminated with PCTFE (Aclar®) high barrier property film.

- Taisei's PVC sheet has a light shielding property even in the ordinary grade and due to no additive of UV organic absorberbent agent that makes free from concern about its influence on the drug.

- To meet your required specifications, it is possible for you to choose a grade having both properties of high moisture permeability and easy-to-press-out the tablet by the combination of PVC Sheet and PCTFE film.

- Wide range of molding temperature with proper formability.

※PCTFE: Polychlorotrifluoroethylene

※Aclar®: Registered by Honeywell

CPP Sheets Laminated with PCTFE (TVS AA)

【Advantages】

- PVC Sheets laminated with PCTFE (Aclar®) high barrier property film

- Short lead time and cost-effective with highly functional sheets.

- Both properties of high moisture permeability and easy-to-press-out the tablet.

- The same as Taisei's PVC sheet, all of the "CPP Sheets Laminated with PCTFE" have the light shielding property due to no additive of UV organic absorberbent agent.

※PCTFE: Polychlorotrifluoroethylene

※Aclar®: Registered by Honeywell

Advantages of Bio-PE Sheets (TAS-BPC)

【Advantages】

- Biomass plastic PE that is authorized by Japan Bio Plastics Association (JBPA) is used for the sheet.

- In comparison with conventional CPP mono-layer sheet, reduction rates of CO2 are under:

TAS-BPC2525: Abt. 24% (Bio-density 25%)

TAS-BPC5025: Abt. 40% (Bio-density 50%) - Wide range of molding temperature, and moldable even in the lower temperature zone. Due to this, possible to reduce the thermal energy.

- Biomass Plastic PE with High-Moisture proof function is used for the core layer.

- TAS-BPC2525

Reg.No.325

"TAS-BPC25 Series"

(Biomass Plastic Rate: 25% or more)

- TAS-BPC5025

Reg.No.383

"TAS-BPC50 Series"

(Biomass Plastic Rate: 50% or more)

One of the global warming factors is the increase of CO2 in the atmosphere when the Petroleum-Origin PE is scrapped ane burned.

When the Sugarcane Origin PE is incinerated, the CO2 is also generated. But this is not regarded as the increasing of CO2, *1 because the origin CO2 was already existed in the atomosphere and was absorbed by sugercane. *2 In addition, the sugarcane is grown up with sun and water and is cropped in every year.

From above 2 matters (*1 and *2), Biomass Plastic what is called "Sustainable Energy Material" and also called the "Carbon Neutrality" due to the carbon saving property.

Obtained the "Certificate of Safety"

- Passed the "Notification 370 of Ministry of Health, Labor, and Welfare"

- Obtained the "Certificate of HOSPA"

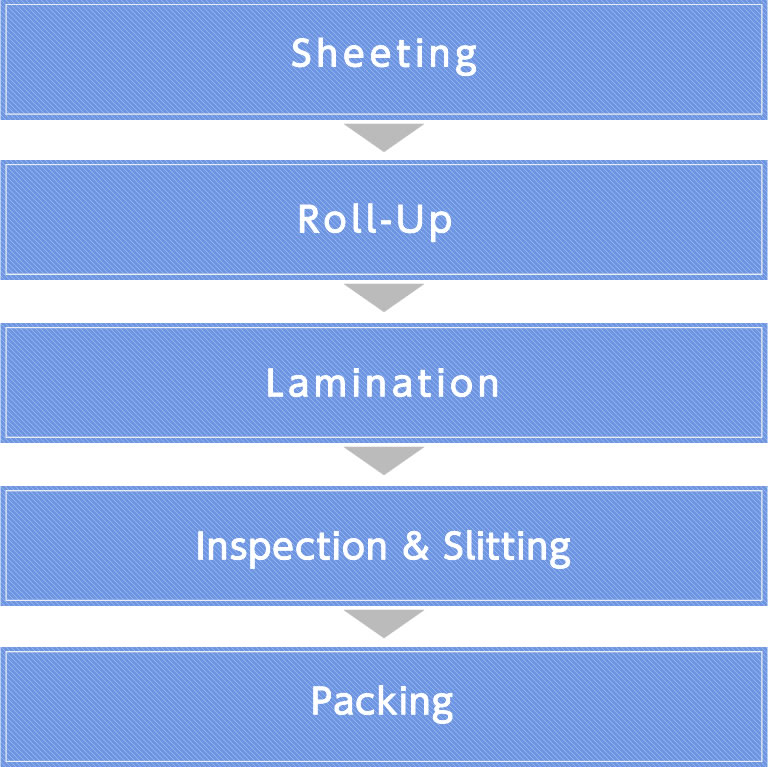

Manufacturing processes of PTP Sheets