Containers for solid product

Series of containers for slid product having highly moisture proof

Due to both our strict deliberation of materials especially for safety and our longtime accumulated knowhows on our technologies, we accomplished to make highly airtight containers. In accordance with GMP regulations, our unique molding systems made it possible to manufacture the clean and homogenous containers classified as "Containers for Solid Drug".

Firstly launched in Japan, as for "Sugarcane origin" made primary packaging for pharmaceutical use

Taisei Kako Co., Ltd has been developing containers with the aim of reducing CO2 emissions during disposal and incineration of pharmaceutical containers, and has been able to propose pharmaceutical containers using polyethylene derived from sugarcane.

Until now, biomass plastics had limited on the properties such as heat resistance, water vapor / oxygen permeability, fragility, and other functions, the reason of this made it difficult to adopt them for the pharamaeutical containers. The new biomass PE container proposed here has almost the same functions and physical properties of the convetional petrochemical resins.

We intend to contribute to the creation of a sustainable society in the pharmaceutical industry with this new container.

Obtained biomass plamarks

Biomass Plamarks are given to products using Biomass Plus, such as plant origin plastics, by JBPA

- Reg.No.253 "IB Bottle Series" (Biomass Plastic Rate:90% or more)

Reg.No.233 "DB Bottle Series" (Biomass Plastic Rate:90% or more)

What is sugarcane origin polyethylene?

Petroleum-oigin polyethylene generates CO2 when it is discarded and incinerated, which increases the concentration of CO2 in the air and causes global warming when CO2 is generated by burning the cane-derived polyethylene. However, it is not considered to be an increase of carbon dioxide gas in the air, because the carbon was originally present in the air and absorbed into the body by plants. Also, if there is solar energy or water, it is rengenerated in every year. From these two points, biomass is said to be a sustainable energy resource, and this peoperty is referred to as "carbon neutral".

It is said that CO2 emissions throughout the entire life cycle, including the production of sugarcane-origin polyethylene is about 70% less than that of petroleum-origin polyethylene.

Series of containers for solid product made by Taisei Kako

We deal with 3types of molding products by "Injection molding", "Injection-blow molding" and "Extrusion blow molding". We will introduce the advantages of the moldings respectively.

Advantages of injection blow molding for wide bottle made of high density polyethylene

TIB series

- Conforming to Article 370 "Notification of Ministry of Health, Labour and Welfare"

- Registration of DMF(Drug Master File): NO.8884

- TIB-35~235 Reg.No.253 "IB Bottle Series" (Biomass Plastic Rate:90% or more)

TIB-270~585 Reg.No.233 "DB Bottle Series" (Biomass Plastic Rate:90% or more)

【Advantages】

- Due to precise molding of mouth part, the bottle holds high air-tightness.

- No need of secondary processing makes the product more cleanliness.

- Due to small variation of its product weight, weight-filling of the content is possible.

- Due to made of olefin base resin, excellent in disposability.

- Available the cap, with or without the knurling.

Our "Injection blow molding" is possible to use resins such as PP, COP, PET, PEN and Bio-PE. Furthermore, it is to possible to make a thick / thin wall of which the bottle made of such resins and others.

| Bottle | Total height (mm) |

|||

|---|---|---|---|---|

| Product name | OFV (mL) |

Diameter of body φ (mm) |

Total height (mm) |

|

| TIB-35 | 32.6 | 35.0 | 50.4 | 54.0 |

| TIB-45 | 44.2 | 38.0 | 55.9 | 59.5 |

| TIB-55 | 54.0 | 40.5 | 58.1 | 61.7 |

| TIB-65 | 64.3 | 40.5 | 66.0 | 69.6 |

| TIB-75 | 71.8 | 45.0 | 62.6 | 66.4 |

| TIB-85 | 81.8 | 45.0 | 69.0 | 72.8 |

| TIB-95 | 92.0 | 47.0 | 71.2 | 75.0 |

| TIB-105 | 105.5 | 47.0 | 78.6 | 82.4 |

| TIB-135 | 133.6 | 51.5 | 82.9 | 86.7 |

| TIB-165 | 160.0 | 55.5 | 85.4 | 89.3 |

| TIB-185 | 183.3 | 55.5 | 97.3 | 101.2 |

| TIB-205 | 206.6 | 58.0 | 97.4 | 101.3 |

| TIB-235 | 235.0 | 60.0 | 106.1 | 110.0 |

| TIB-270 (DB) | 272.0 | 63.0 | 112.4 | 116.3 |

| TIB-335 (DB) | 335.0 | 66.6 | 122.0 | 125.9 |

| TIB-385 (DB) | 384.0 | 69.9 | 124.2 | 128.6 |

| TIB-485 (DB) | 480.7 | 76.2 | 129.9 | 134.3 |

| TIB-585 (DB) | 584.0 | 79.2 | 144.9 | 149.3 |

TIB-TE series

- Conforming to Article 370 "Notification of Ministry of Health, Labour and Welfare"

- Registration of DMF(Drug Master File): NO.8884

- Reg.No.253 "IB Bottle Series" (Biomass Plastic Rate:90% or more)

Registered only the bottle

Round-shape containers for solid product by "Injection blow molding"

Cap with TE function.

【Advantages】

- Due to delaying the timing between the "cap-opening" and the "belt-cutting", you can feel the completion of the "opening" of the cap for the first time.

- Once the belt is cut and downed below, the user can easily find that the bottle was already opened.

- Since the belt-cutting portion does not come off from the ring of the bottle, it does not interfere with taking the tablets.

- Once the "belt" portion is cut and downed, no need for extra force except the "Tightening Torque". This will make the control easier.

- The molding gasket and the moisture proof tank are common-use of TIB bottles, and keep the high airtightness.

| Bottle | Total height (mm) |

|||

|---|---|---|---|---|

| Product name | OFV (mL) |

Diameter of body φ (mm) |

Total height (mm) |

|

| TIB-75 (TE) | 77.4 | 45.0 | 70.9 | 74.4 |

| TIB-85 (TE) | 88.6 | 45.0 | 77.8 | 81.3 |

| TIB-95 (TE) | 100.0 | 47.0 | 80.4 | 83.9 |

| TIB-105 (TE) | 112.6 | 47.0 | 86.9 | 90.4 |

| TIB-165 (TE) | 170.6 | 55.5 | 94.6 | 98.3 |

| TIB-235 (TE) | 246.1 | 60.0 | 115.70 | 119.40 |

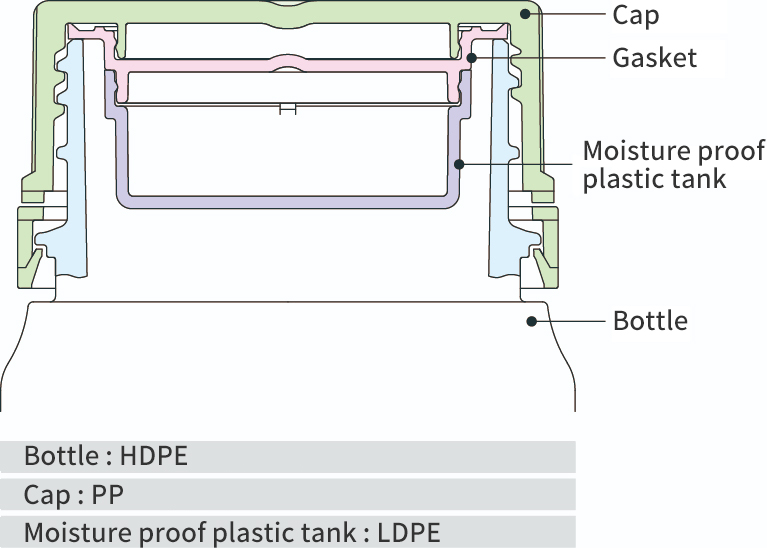

TIB-(CR-SF+TE) series

- Conforming to Article 370 "Notification of Ministry of Health, Labour and Welfare"

- Registration of DMF(Drug Master File): NO.8884

- CR Certification No. of ISO8317 : ivmZERT234467042008-8317

- CR Certification No. of CFR 1700.20 : ivmZERT234467042008

- Reg.No.253 "IB Bottle Series" (Biomass Plastic Rate:90% or more)

Registered only the bottle

Round-shape containers for solid roduct by "Injection blow molding".

Caps with both functions of TE and CR.

The bottle can be opend to rotate the cap with pressing the top-surface of the cap.

【Advantages】

- Gained CR certificates of USA and Europe

- We believe that this would be the best method to protect children from the accidental ingestion.

- Since having both functions of the CR and the TE, this will make it possible to improve your risk management against counterfeit drugs.

- The molding gasket and the moisture proof tank are common-use of TIB bottles, and keep the high airtightness.

※Children aged from 42 to 51months old and adults aged from 50 to 70 years old were tested.

| Bottle | Total Height (mm) |

|||

|---|---|---|---|---|

| Product name | OFV (mL) |

Diameter of body φ (mm) |

Total height (mm) |

|

| TIB-75 (TE) | 77.4 | 45.0 | 70.9 | 83.5 |

| TIB-85 (TE) | 88.6 | 45.0 | 77.8 | 90.4 |

| TIB-95 (TE) | 100.0 | 47.0 | 80.4 | 93.0 |

| TIB-105 (TE) | 112.6 | 47.0 | 86.9 | 99.5 |

Advantages of extrusion blow molding for wide bottle made of high density polyethylene

TCB series (Square)

- Square standardization bottle, which is complied with Drug package standardization committee

- Conforming to Article 370 "Notification of Ministry of Health, Labour and Welfare"

- Registration of DMF(Drug Master File): NO.8884

- Reg.No.233 "DB Bottle Series" (Biomass Plastic Rate:90% or more)

Upper surface of the mouth portion is finished with smooth and seamless.

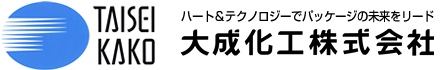

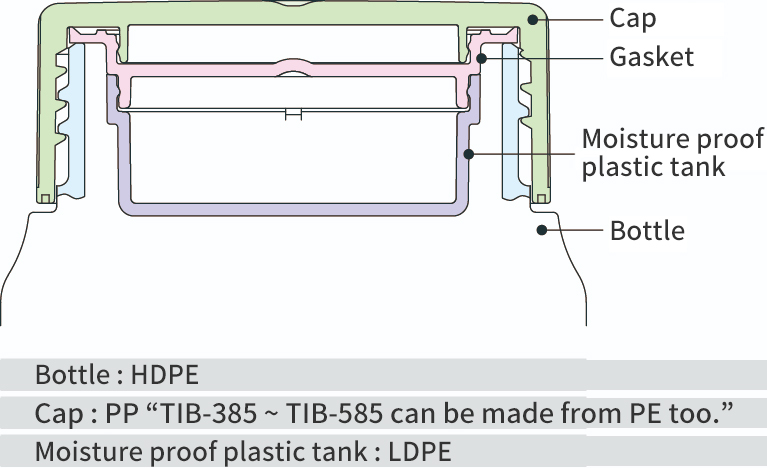

HDPE wide-orifice container with excellent function of air-tightness.

【Advantages】

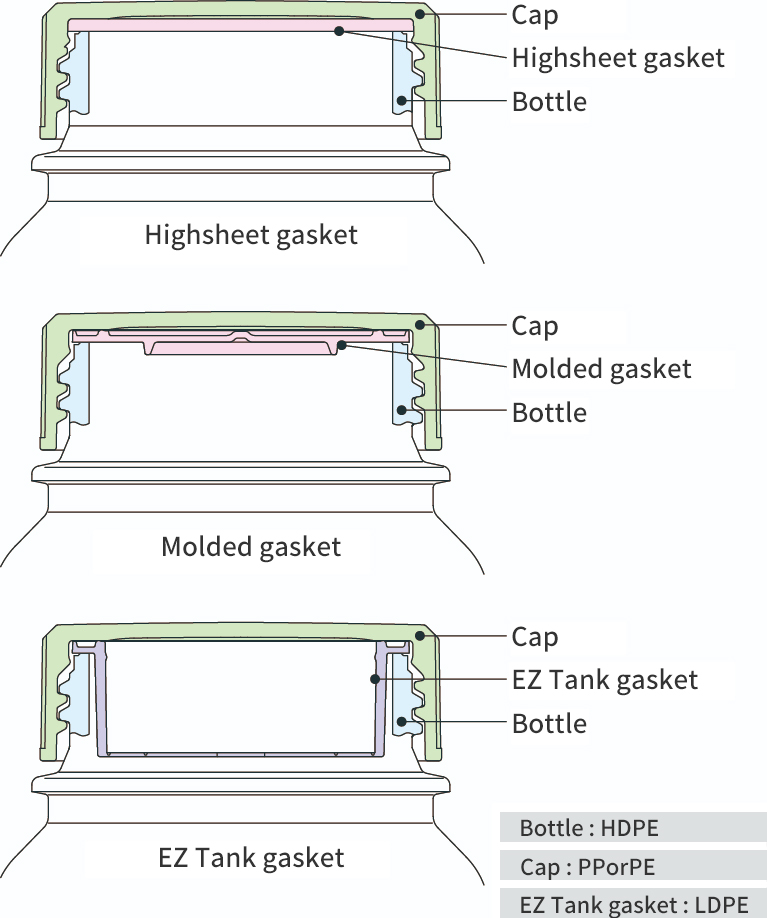

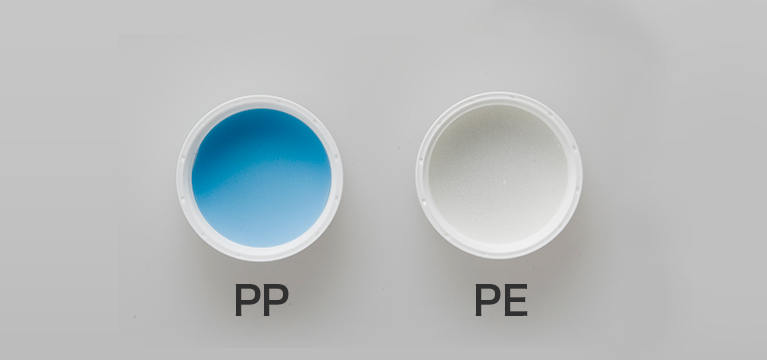

- Available 2kinds of materials on the cap, either PP or PE.

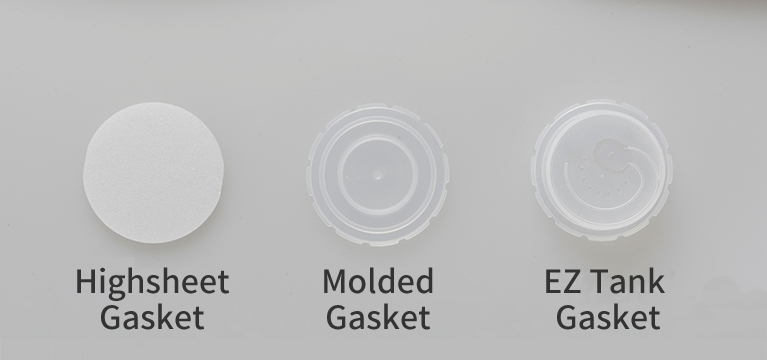

(To identify the material, the color of the gasket is differewnt from each other.) - Available 3 kinds of gaskets: "Highsheet gasket", "Molded gasket" and "EZ tank gasket possible to put the drying agent in the void space".

- The configuration of the "EZ tank gasket" is to pick out the drying agent easily, and this will make it possible to dispose separately.

- Due to the shape of square, this will make lesser the dead space and easier to read the indication.

※ EZ: Eco Zip

| Bottle | Total Height (mm) |

|||

|---|---|---|---|---|

| Product name | OFV (mL) |

Diameter of body φ (mm) |

Total height (mm) |

|

| No.1 | 35.0 | 34.6 | 51.5 | 55.2 |

| No.2 | 45.3 | 37.0 | 58.5 | 62.2 |

| No.3 | 69.5 | 44.0 | 62.0 | 65.7 |

| No.4 | 93.0 | 48.0 | 65.0 | 68.7 |

| No.5 | 114.0 | 48.0 | 75.0 | 78.7 |

| No.6 | 134.0 | 52.0 | 77.5 | 81.1 |

| No.7 | 183.0 | 60.0 | 78.5 | 82.2 |

| No.8 | 223.0 | 60.0 | 91.5 | 95.2 |

| No.9 | 272.0 | 64.0 | 98.0 | 101.7 |

| No.10 | 338.0 | 68.5 | 101.5 | 105.9 |

| No.11 | 392.0 | 68.5 | 114.0 | 118.4 |

| No.12 | 497.0 | 68.5 | 139.5 | 143.9 |

| No.13 | 598.0 | 72.5 | 151.0 | 155.4 |

| No.14 | 1066.0 | 100.0 | 159.0 | 163.5 |

| No.15 | 1277.0 | 100.0 | 181.5 | 186.0 |

Buffer materials of containers for solid product

Dealing with many primary packages for pharmaceutical products, we are also challenging on the development of buffer materials that are enclosed in the containers to protect the product.

Advantages of CPMB

- Conforming to Article 370 "Notification of Ministry of Health, Labour and Welfare"

A buffer material in the form of rolled-up elastic polyethylene net obtained by extrusion molding.

Put the net in the inner space of the bottle, it protects the drug from vibration and shock during the processes such as transportation and etc.

【Advantages】

- Due to having its high flexibility, CPMB is adjustable to fit various kinds of head spaces of the bottles.

- Put it in the inner space of the bottle, it protects the drug from vibration and shock during the transportation.

- Due to having its "pull-up portion" of the CPMP, this makes easier to take it out from the bottle without "rolli-up the tablets".

| Size | Outer diameter φ (mm) |

Length of the net (mm) |

Quantity per case |

|---|---|---|---|

| CPMB NO.1-300HS | 45±10mm | 320±20mm | 1,000 |

| CPMB NO.1-400HS | 45±10mm | 420±20mm | 1,000 |

| CPMB NO.1-500HS | 45±10mm | 520±20mm | 900 |

| CPMB NO.2-400HS | 55±10mm | 420±20mm | 750 |

| CPMB NO.2-500HS | 55±10mm | 520±20mm | 600 |

| CPMB NO.2-700HS | 55±10mm | 720±20mm | 500 |